Potting and Spacing

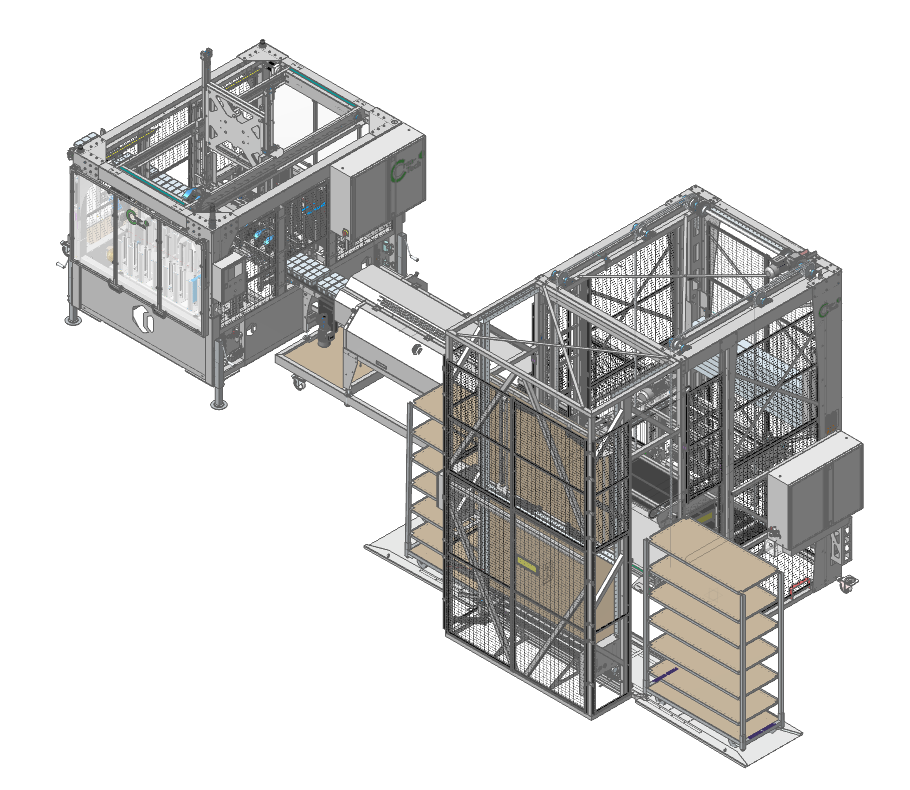

At Artisan Orchids, an orchid grower from the Netherlands, we installed the container system and a potting and spacing robot (gantry). The robot picks 2,500 pots per minute, from two different conveyors.

Then, it places young plants (just potted ones) close to each other on a container. The more grown plants with collars are placed wider apart on a container.

Minimising Risk

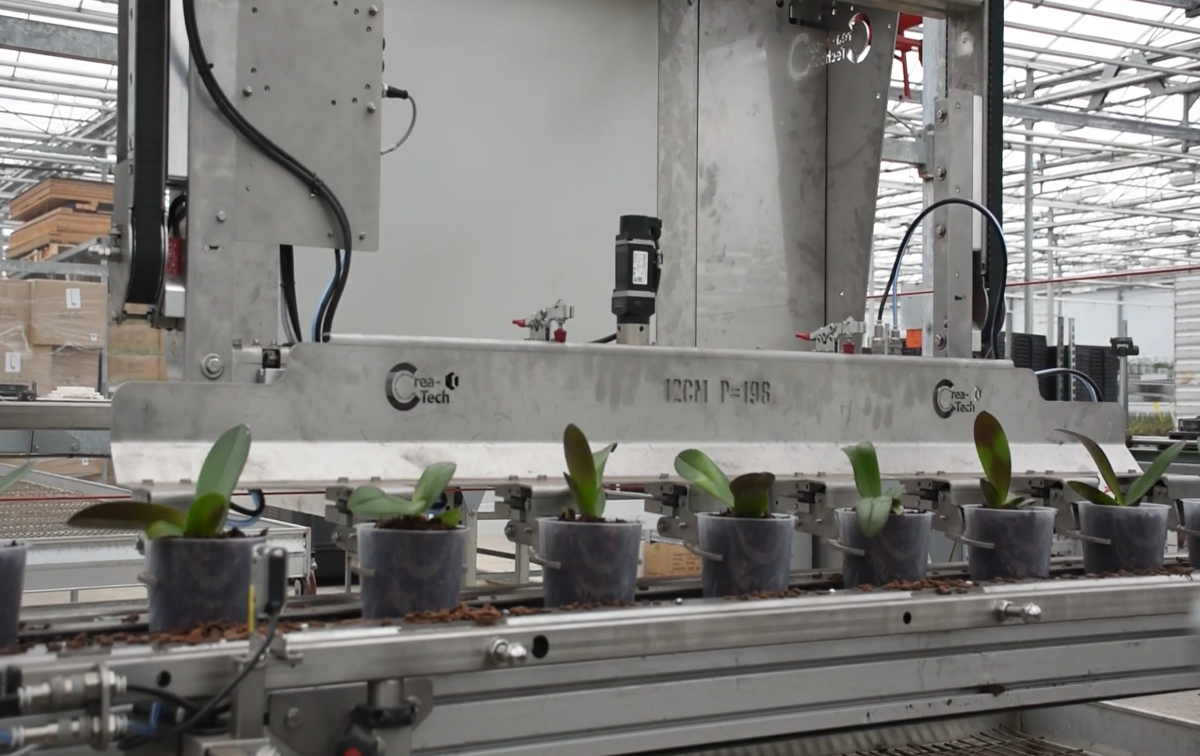

We installed one robot that does both potting and spacing. With 1 fork, 8 plants are put away in a row both times. The robot has two depositing positions; one for the potted plants and one for the plants to be widened.

The planting position of the potting line are fitted with a push-on plate for pushing up the row of potted plants. The fork is fitted with individual pinch grippers. This way, each plant is grabbed individually, minimising the risk of interference. The cups are stopped by different pneumatic cylinders. So that exactly 8 plants fit in the container with equal distance between them.

Servo-controlled

The potting and spacing robot is servo-controlled. This allows the movements to be programmed and changed with high precision. This has the great advantage that the robot can be set separately for each plant type or plant phase.

Within a certain plant group, the movements for potting can be different from those for widening. These settings can be stored in the menu functions, which are easily operated via the control display. Because the movements can be better controlled, higher capacity can be achieved.

Design

We have taken great care in the final design. The robot does not obstruct the overview on the work floor. This also results in better accessibility of the machine.

The machine is composed of high-quality materials, so service intervention is low. The frame is made entirely of stainless steel and is modular, keeping manufacturing costs to a minimum.

Artisan Orchids

Artisan Orchids has been growing phalaenopsis on 2.5 hectares in the greenhouse area ‘de Bommelerwaard’ in Nieuwaal since 2006. Artisan sets itself apart with its superior quality orchids. A compact Phalaenopsis with lots of branches and flowers.

Artisan also strives to create a resilient product, an orchid with an extra-long flowering period which allows high-end florists and garden centres to differentiate themselves. They offer a collection of around 40 different varieties in a wide range of colours.