Turnkey Miniplug (tree) Facility

Maelor Forest Nurseries grows their 25 million Sitka Spruce seedlings in the miniplug facility in Wrexham, UK, built as a turnkey project by CMW Horticulture. CMW Horticulture is the brand name of Bosman Van Zaal within the UK region.

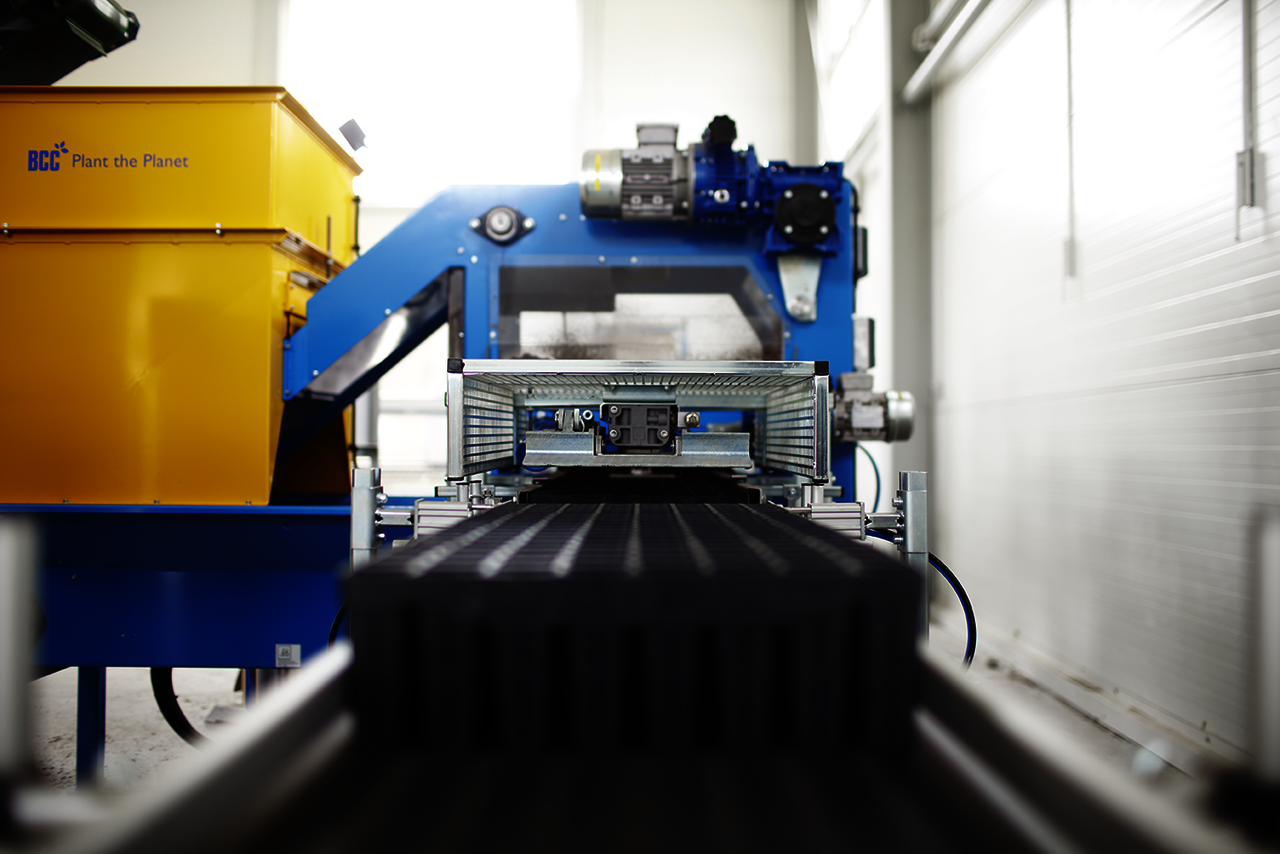

The project includes a film covered greenhouse (Venlo type multi span of 12,8 m bay width) of 25,446 m2; 1,792 m2 of working area; irrigation and electrical installations; over 2,000 containers with transport systems; a Viscon seeding line and plug fixers; a BCC mixing and filling line; and Urbinati and BCC spraying booms. BCC also supplied a tray-washer.

Film covered greenhouse

For Maelor Forest Nurseries, we engineered and built a Venlo type, multi span, film covered greenhouse of 4.0 m in height to the gutter and 25,446 m2 total area; including doors, hatches, and the like; and a 1,792 m2 working area.

Complete irrigation and electrical design

Part of the turnkey project are the irrigation and electrical installations by Bosman Van Zaal. We installed a spraying/misting system; one inside fertiliser pump and one for the outdoor fields; clean water pumps and three silos of each 94 m3; water supply and tap points; horizontal fans, work lights, and all necessary panels, sockets, and supplies.

Significantly reducing manual handling

“Our miniplug facility consists of three elements, a seed sowing line, covered growing area, and outdoor hardening off space. All three elements are connected by a roller bench system, which significantly reduces manual handling of trays,” says Maelor Forest Nurseries.

For the outdoor holding area and for the indoor area we made over 2,000 containers with mesh bottoms. The installation includes supports and rail tracks, lifting conveyor frames, stoppers, drive wheels, push and pull units, a container (de-)stacker, a disinfection unit, a turning unit, a manual transport train, and all necessary electrical connections.

Incorporated special partner equipment

Bosman Van Zaal also installed third party equipment, such as 11 bays of Urbinati spraying booms indoors, two outdoor BCC spraying booms and a climate control system.

Special supplier equipment in this project include a Visser Systems roulette seeding line, two Pic O Mat Vision/Gapping transplanters. Also, a BCC stacker, mixing and filling line, and a tray washer are installed. The tray washer consists of a high-pressure unit for mechanical cleaning and hot water washer for thermal disinfection.

Maelor Forest Nurseries

Maelor Forest Nurseries Limited is located at Fields Farm, Bronington on the Welsh Borders. They also have a nursery site based at Darnaway, Forres, in the Scottish Highlands. The nursery is part of the BSW Group and Binderholz and produces an extensive range of commercial forestry and native broadleaf species, marketing approximately 35 million trees a year to customers throughout the UK and Europe.

“Maelor Forest Nurseries miniplug facility will secure not only a continuous and steady supply of tree stocks but also improve their quality and resilience to the effects of climate change”, says Maelor Forest Nurseries.