High quality tomatoes for Japan

In Misaka Town, Japan, TMJ Greenhouses grows their quality tomatoes in a unique turnkey and high-tech film covered greenhouse. The greenhouse and installations were designed and build by Bosman Van Zaal, under the supervision of partner Inochio Agri Inc. The whole building phase on site took 9 months.

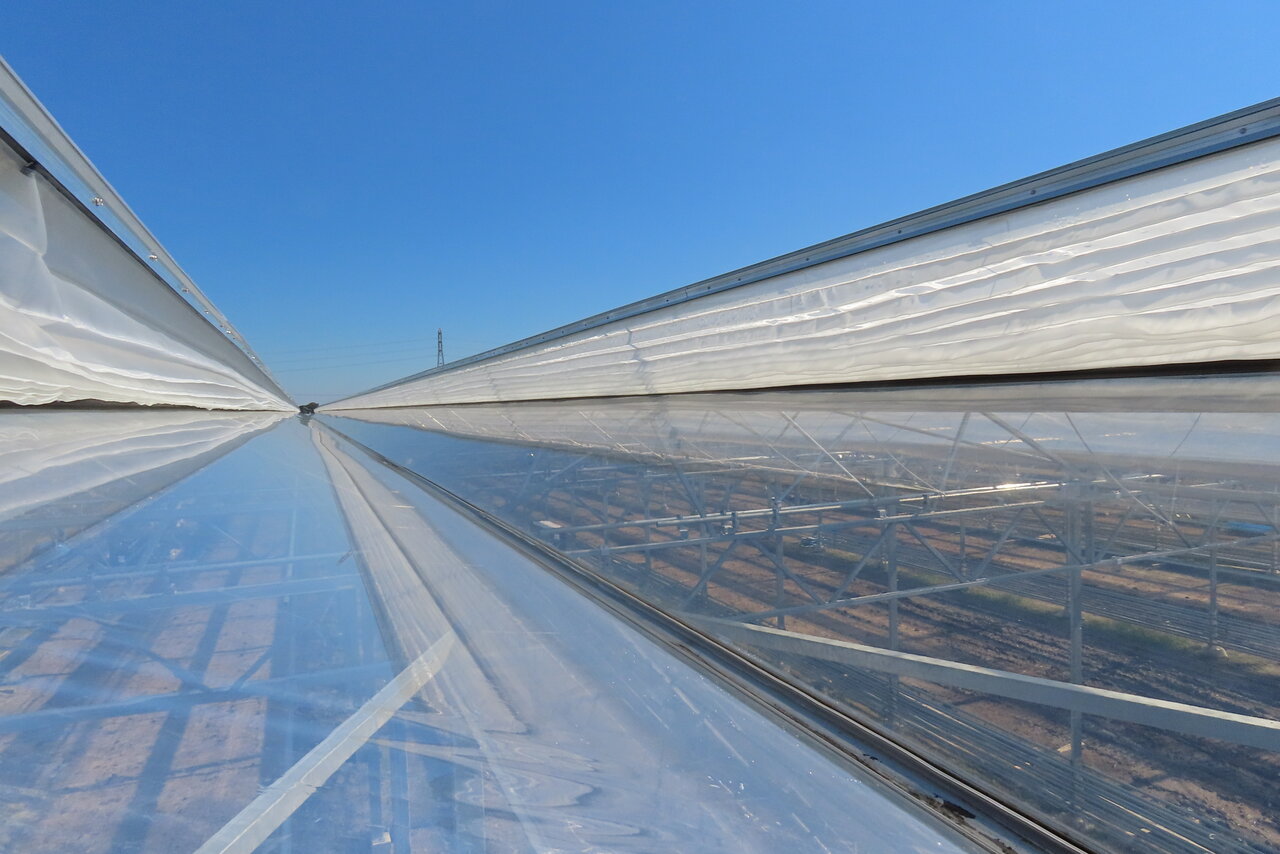

F-CleanTM covered greenhouse

The Bosman Van Zaal greenhouse, build by partner Inochio, is a special Venlo greenhouse since it is completely covered with F-Clean film. The greenhouse is 39,475 m2 and earthquake, strong wind, and snow load proof. It also includes insect netting, and (Svensson) screens. Also part of the project are work and service areas. The greenhouse consist of 9 compartments.

F-CleanTM is a high-quality Teflon film that transmits more light (up to 94%) than glass, PE film and other greenhouse cladding materials. Moreover, specific properties can be formulated for UV transmission or blocking. With respect to diffuseness, different haze factors are available. The high light transmission and flexible properties results in optimal light conditions, higher production, and better quality. Moreover, no condensation forms on the film and is self-cleaning. And, depending on local climate conditions, the lifespan is up to 25 years. F-CLEANTM is a trademark of AGC Green-Tech Co. Ltd.

Special HVAC installations

To assure growing in a constant and efficient climate, the ClimaPoraTM/® concept of Bosman Van Zaal was chosen. The ClimaPora TM/® system for cooling and dehumidification is applied to all 9 compartments of the greenhouse. Furthermore, several heating installations are installed, such as boilers, condensers, tanks, tube rail heating, CO2 units, and more.

ClimaPoraTM/® is a semi-closed greenhouse concept, consisting of an air treatment and control chamber integrated within the greenhouse. It offers the possibility to cool, heat, humidify, dehumidify or a combination of these options from inside or outside the greenhouse. The ClimaPora is highly effective and very efficient with respect to electricity consumption compared with alternative systems. There is less insect pressure due to overpressure. The ClimaPora can be equipped with both adiabatic and mechanical cooling. Due to the semi-closed character of the greenhouse, the efficiency of CO2 consumption is increased. Cooling capacity of 3,000 kW, and at night 76 W/m2. Shade screen with 15% energy saving, energy screen with 47% energy saving. Air circulation of 60 m3/h per m2 greenhouse. And heat transmittion outside > inside of 76 W/m2 per m2 greenhouse. Among which inside and outside air shutters, and axial fans.

Fully controlled and sustainable facility

Daily fresh water from a nearby well is used for the irrigation of the tomatoes, through drip irrigation in gutters with Rockwool. For this, Bosman Van Zaal developed and Inochio installed a multi media filtration system, silos, mixing tank irrigation units, fertiliser and acid tanks, a high pressure fog system and a clean water installation. 100% Of the drain water is reused, thanks to a drain water collection and UV disinfection unit with sand filter.

All electric, automated and irrigation systems are analysed and controlled by the IIVO control system and necessary software, to measure CO2, humidity, cooling, heating, irrigation, energy, and more.