Climate Computers

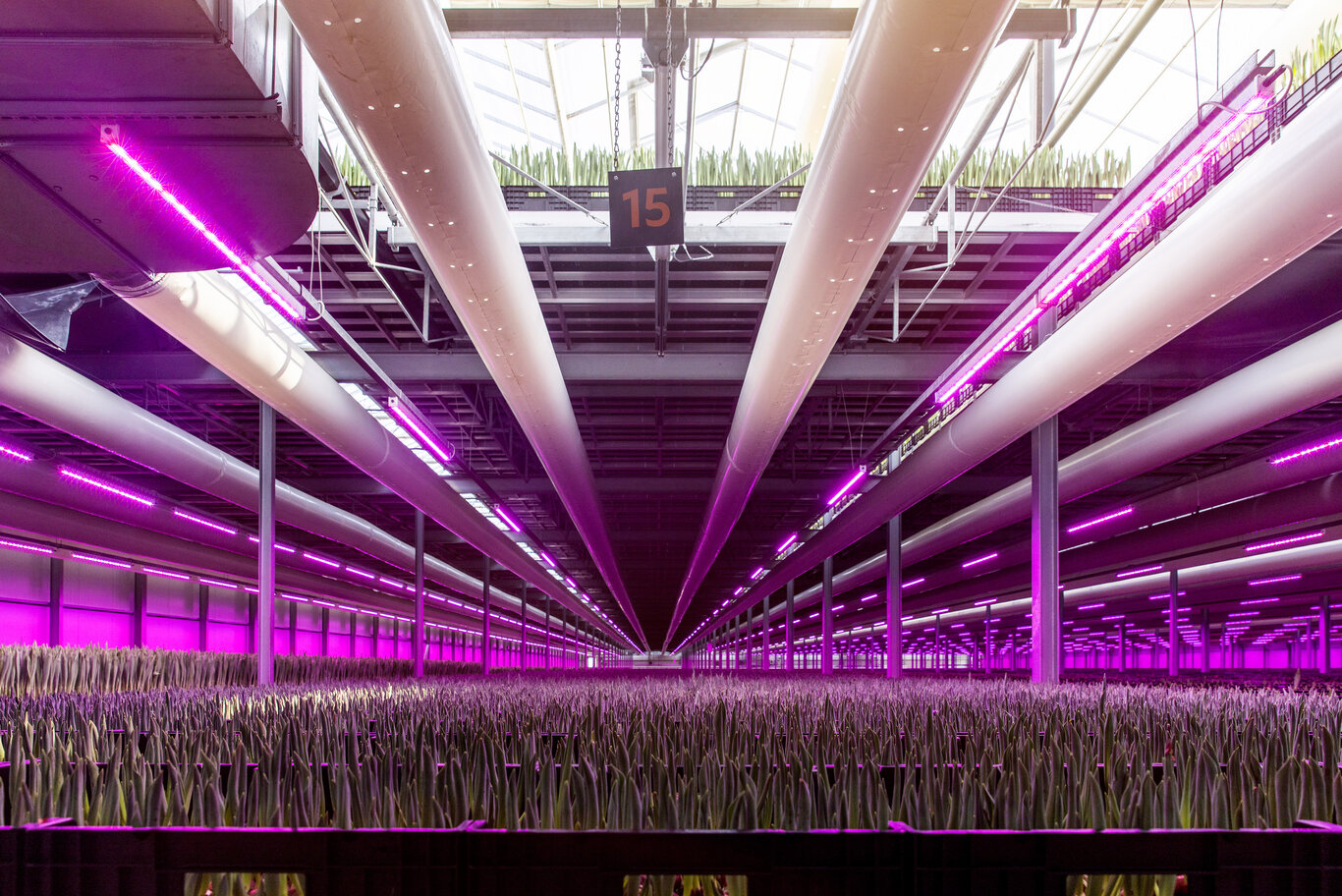

Growing is a matter of creating the best climate conditions. An ideal mix of heating, cooling, circulation and automation results in a better, stronger, and healthier crop and higher yields at lower costs.

Bosman Van Zaal understands the crucial role of maintaining ideal environmental conditions for successful indoor farming and controlled environment agriculture (CEA). Our comprehensive HVAC solutions combine 100 years of horticultural expertise with 30 years of indoor farming experience.

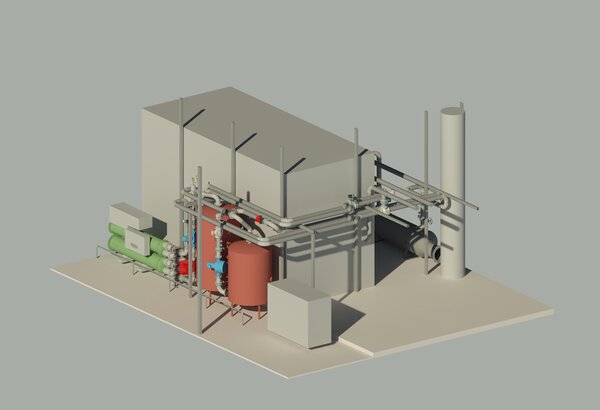

We understand that every CEA operation has unique requirements. Our team of experts will work closely with you to assess your specific climate, crop needs, and budget to recommend the most effective solution. This may include:

Growing is a matter of creating the best climate conditions. An ideal mix of heating, cooling, circulation and automation results in a better, stronger, and healthier crop and higher yields at lower costs.

An electric boiler, the key to your successful and affordable energy mix?

Save energy with your existing CHP or boiler installation! With a second flue gas condenser

Sustainable and economical heating with solar thermal energy generation

Making current businesses more sustainable with a heat pump and electric boiler

Adiabatic cooling is based on the thermodynamic principle that evaporating water draws heat from its environment resulting in a lower ambient temperature.

Mechanical cooling is used in greenhouses in situations where the outside conditions (high humidity) do not permit the use of alternatives based on adiabatic cooling.

Circulation fans offer a solution for every indoor climate challenge.

Cultivate optimal plant growth with Bosman Van Zaal's advanced Plant Growth Chambers & Controlled Environment Rooms.